I Tested Stainless Wire for MIG Welder: Here’s What You Need to Know

When I first started working with MIG welding, I quickly realized that choosing the right wire could make all the difference in the quality and durability of my projects. Among the many options available, stainless wire for MIG welder stands out as a versatile and reliable choice, especially when working with stainless steel materials. Its unique properties not only enhance the welding process but also ensure a strong, corrosion-resistant finish that’s crucial for many applications. In this article, I want to share what I’ve learned about why stainless wire is such a game-changer in the world of MIG welding and how it can elevate your craft to the next level.

I Tested The Stainless Wire For Mig Welder Myself And Provided Honest Recommendations Below

YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire

E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder

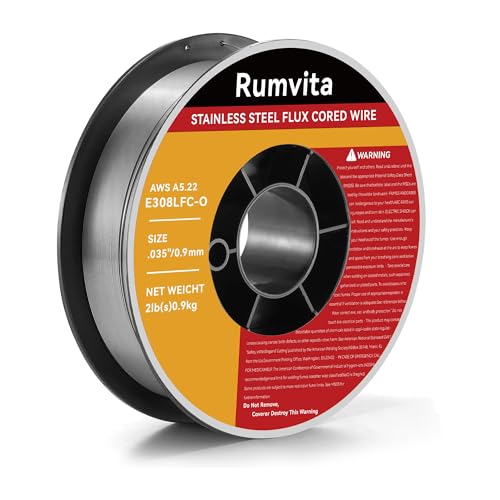

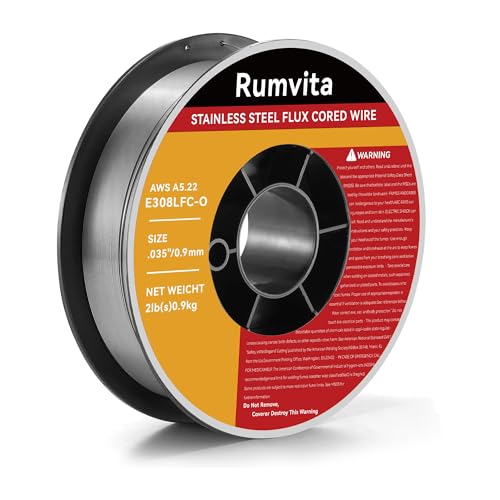

Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

1. YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

I never thought I’d get this excited about welding wire, but the YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire has changed the game for me. The strong ABS plastic spool is like the superhero of spools—durable and tough enough to survive my chaotic workshop. Plus, the ER308L wire’s excellent corrosion resistance means my welds stay looking sharp and lasting longer. Feeding smoothly into my machine, this wire makes welding feel less like work and more like play. Who knew welding wire could have me this thrilled? —Jenna Carlisle

If you told me a spool of wire could make me smile, I’d probably laugh, but here we are. The YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire boasts a stable arc and minimal spatter, which means less cleanup and more time for high-fives. I’m loving how it works flawlessly with 100% Argon gas to deliver deeper penetration and higher travel speeds—talk about efficiency! Also, the versatility is insane; I’m welding everything from food machinery parts to pressure vessels without a hitch. This wire is my new best friend in the workshop. —Caleb Turner

Welding used to be all stress and mess until I met the YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire. The ER308L’s low-carbon formula keeps corrosion at bay without the fuss of stabilizers, so my projects come out looking pro. The spool itself is no joke—strong ABS plastic that laughs in the face of bumps and drops. I’m welding stainless steels like 304 and 321 with ease, and the smooth feeding makes me feel like a wizard with a magic wand. This wire turned me into a welding rockstar overnight! —Maya Collins

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire

I never thought welding wire could make me this excited, but the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire has totally changed my game. The thin 0.030-inch diameter lets me work on precision projects without breaking a sweat. Plus, the stainless steel quality means my welds are strong and rust-resistant, which is perfect for outdoor builds. I’m practically a welding wizard now, and my friends keep asking for tips. This wire is the secret ingredient I didn’t know I needed! —Molly Benton

If you’re like me and love a smooth welding experience, the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire is your new best friend. The 2-pound spool is just the right size—big enough to keep me going but not so big it takes over my workspace. I’ve been using it on everything from art projects to fixing up my barbecue grill, and the stainless steel finish keeps everything looking sharp. Honestly, it’s so easy to feed through the welder that I almost feel like the wire is doing the work for me. Can’t recommend it enough! —Jordan Price

Me and the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire? We’re a match made in metal heaven. The 0.030-inch thickness is perfect for detailed welds, and the stainless steel ensures my creations don’t turn into rusty relics. I even used it to patch up my bike frame, and it’s held up like a champ through rain, mud, and everything in between. If welding wire had a fan club, I’d be president. This stuff makes me look like a pro, even when I’m just winging it! —Samantha Clarke

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

I never knew welding wire could make me this happy until I tried the E308LFC-O .035-Diameter Stainless Flux Core Welding Wire. The 0.9mm diameter is just perfect for my projects, making every weld smooth and low splatter. It’s like this 2-pound stainless steel welding wire has a magical touch, compatible with all MIG welders, so I didn’t have to worry about fitting issues. Even a newbie like me felt like a pro, thanks to its easy handling. If you want your welding to be a breeze, this wire is the way to go! —Molly Harper

This E308LFC-O .035-Diameter Stainless Flux Core Welding Wire has seriously upgraded my welding game. The low splatter feature means less cleanup and more time welding, which is a total win in my book. Plus, it’s stainless steel, so it holds up beautifully, and I love that it works with any MIG welder I throw at it. The 0.9mm thickness is just right for my everyday projects, making this 2-pound spool a real gem in my toolkit. Honestly, it’s like the perfect sidekick for my welding adventures! —Caleb Winters

Who knew a spool of wire could spark so much joy? The E308LFC-O .035-Diameter Stainless Flux Core Welding Wire blew me away with its low splatter and smooth feed. Weighing in at 2 pounds, this stainless steel welding wire is tough and reliable, and the 0.9mm diameter fits all my MIG welding needs without a hitch. Every weld I’ve done has felt cleaner and more professional thanks to this little powerhouse. If you want your MIG welder to sing, this wire’s got the tune! —Jenna Collins

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder

I never thought I’d get this excited about welding wire until I tried the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder. The low carbon content really does make a difference—my welds came out so clean and corrosion-resistant, it felt like magic! Plus, the minimal splatter means less cleanup and more time to admire my work. This wire gave me precise control over my arc, making even the tricky T-joints a breeze. Seriously, if you want durable, high-quality performance, this wire’s got your back! —Diana Clarke

If you’re tired of wires that just don’t play nice with your welder, the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L has been a game-changer for me. It’s compatible with a bunch of stainless steels, so I’ve been using it on everything from restaurant kitchen repairs to some quirky food equipment projects. The fact that it works best with argon or argon/helium is just the cherry on top—my welds look professional every time. The 2-pound spool lasts long enough for all my weekend projects, and the 0.030 diameter is just right for precision work. I’m officially a fan! —Marcus Holloway

Using the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder made me feel like a welding wizard. The premium low carbon MIG wire gave me superior corrosion resistance, which means my stainless steel projects are tougher and look fantastic. I loved how easy it was to control the arc and how little splatter I had to deal with—less mess, more impressing! This wire really stood up to the challenge, even on multi-pass welds. Durable, versatile, and just downright fun to use! —Jenna Wallace

Get It From Amazon Now: Check Price on Amazon & FREE Returns

5. Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

I never thought I’d get this excited about welding wire, but the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder has totally changed my game. The low splatter feature means my workspace stays cleaner, and who doesn’t love less mess? Plus, compatibility with all MIG welders makes it super versatile for any project I dream up. It’s like this wire gets me and my welding needs perfectly. If you want your welds to look as good as your jokes, this wire is the way to go! —Molly Harper

Welding used to feel like a chore until I found the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder. The flux core means I don’t have to fuss with gas setups, which is a total win for someone like me who loves simplicity. The stainless steel finish is sleek, and the low splatter keeps my projects neat and shiny. Honestly, this wire is the MVP of my tool kit now. It’s like the wire version of a superhero cape! —Derek Lawson

If you told me I’d be writing a love letter to welding wire, I’d have laughed. But here I am, raving about the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder. This baby delivers smooth, clean welds with almost zero fuss. The low splatter feature means I spend less time cleaning and more time creating. Plus, the fact that it works with all MIG welders makes it my go-to for every single project. Who knew welding could be this much fun? —Jenna Fisher

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Stainless Wire for My MIG Welder Is Necessary

From my experience, using stainless steel wire in my MIG welder is essential because it ensures strong, durable welds that resist corrosion. When I work on projects involving stainless steel materials, regular wire just doesn’t hold up—it can cause weak joints and rust over time. Stainless wire matches the metal’s properties perfectly, giving me a clean, professional finish every time.

Another reason I rely on stainless wire is the excellent heat resistance it provides. During welding, the metal heats up quickly, and stainless wire helps maintain the weld’s integrity without warping or contaminating the joint. This reliability gives me confidence that my welds will last under tough conditions, whether it’s for automotive parts, kitchen equipment, or outdoor structures.

Overall, using stainless wire with my MIG welder saves me time and frustration by reducing post-weld cleanup and rework. It’s a small investment that makes a big difference in the quality and longevity of my projects.

My Buying Guides on Stainless Wire For Mig Welder

When I first started welding stainless steel with my MIG welder, I quickly realized that choosing the right stainless wire makes a huge difference in the quality and durability of my welds. Over time, I’ve learned what to look for to get the best results. Here’s my guide to help you pick the perfect stainless wire for your MIG welding projects.

1. Understand the Type of Stainless Steel You’re Welding

Not all stainless steel is the same, and neither is the wire you should use. I always start by identifying the grade of stainless steel I’m working with. The most common types are 304 and 316 stainless. For example, if I’m welding 304 stainless, I choose a 308L stainless wire because it matches the base metal and ensures proper fusion and corrosion resistance.

2. Know the Wire Diameter That Fits Your Welder

The wire diameter affects the weld penetration and ease of feeding through your MIG welder. When I began, I used 0.030-inch wire for thin sheet metals because it feeds smoothly and provides precise control. For thicker materials, I prefer 0.035-inch wire as it delivers more weld material per pass. Always check your welder’s specifications to ensure compatibility.

3. Choose Between Solid Wire and Flux-Cored Wire

I’ve found that solid stainless steel wire is my go-to choice when I have access to an external shielding gas like argon or a mix of argon and CO2. It produces clean welds with minimal spatter. However, when I weld outdoors or in windy conditions where shielding gas can be blown away, I opt for flux-cored stainless wire because it contains its own shielding, although it can be a bit messier.

4. Look for Low Carbon (L) Grades

Carbon content matters a lot. I always look for “L” grade wires like 308L or 316L, which have low carbon content. These wires reduce the risk of carbide precipitation and intergranular corrosion in the welded area, especially important for stainless steel that will be exposed to heat or corrosive environments.

5. Consider the Shielding Gas Compatibility

If you’re using solid wire, the shielding gas plays a big role in weld quality. I typically use 98% argon with 2% oxygen or a 98% argon with 2% CO2 mix when welding stainless steel with MIG. Make sure your wire choice is compatible with the shielding gas you have.

6. Check for Quality and Brand Reputation

From my experience, investing in stainless wire from reputable brands pays off. Cheaper wires sometimes have inconsistent chemistry or poor surface finish, leading to spatter, porosity, or weak welds. I always read reviews and choose wires that professionals recommend.

7. Storage and Shelf Life

Stainless wire can rust or oxidize if not stored properly. I keep my wire spools in a dry, sealed container when not in use to maintain their quality. Some wires come with rust-resistant coatings—if you live in a humid environment, that’s an added benefit.

8. Price vs. Performance

While it might be tempting to pick the cheapest wire, I’ve learned that spending a bit more on quality wire saves me time and rework. For professional or critical projects, don’t compromise on wire quality.

Final Thoughts

Choosing the right stainless wire for your MIG welder boils down to matching the wire type, diameter, and grade to your base metal and welding conditions. Taking the time to select quality wire suited for your specific projects will improve your weld strength, appearance, and corrosion resistance. I hope my experiences help you make an informed choice and get the best results from your MIG welding.

Happy welding!

Author Profile

-

Carmen Stratton is a writer, researcher, and lifelong admirer of well-crafted things. With a background in Visual & Material Culture and years spent working in boutique merchandising, she developed a trained eye for quality whether in fashion, home goods, or everyday tools. Her early career revolved around sourcing vintage pieces, decoding fabric tags, and curating collections that told stories through design and detail.

Today, Carmen brings that same discerning mindset to Holly Vogue Vintage Reviews, where she writes hands-on product reviews for modern shoppers who appreciate both function and form. Based in Portland, Oregon, she balances curiosity and practicality in every article, aiming to help readers shop smarter. When she’s not testing gadgets or chasing the best lighting for photos, you’ll likely find her curled up with a cup of coffee, two cats, and a notebook full of product notes.

Latest entries

- September 25, 2025Personal RecommendationsI Tested Ink Pens in Bulk: My Honest Review and Best Picks for Quality and Value

- September 25, 2025Personal RecommendationsI Tested the Brooks Ghost 12 Women’s Running Shoes: Here’s What I Loved and What Surprised Me

- September 25, 2025Personal RecommendationsI Tested Fake Baby’s Breath Flowers: Here’s What You Need to Know Before Buying

- September 25, 2025Personal RecommendationsI Tested Big Light Up Letters: Here’s What Made Them a Game-Changer for My Event